In industrial manufacturing, some scenarios require materials to both “withstand heavy loads” and “endure repeated stresses”—for instance, aerospace structural components must bear vibrations and impacts during flight, tooling fixtures need to repeatedly clamp workpieces without deforming, and connectors in high-pressure vessels must resist leakage under long-term pressure. With its combined advantages of “ultra-high strength, excellent machinability, and good fatigue resistance,” 2012 high-strength hard aluminum has become the “preferred material” for such demanding applications, playing an irreplaceable role in aviation, machinery, military industries, and other fields. Foshan Zhanmei Metal, with over 40 years of expertise in aluminum processing, ensures the full performance potential of 2012 hard aluminum through precise process control, meeting the high-strength requirements of diverse industrial scenarios.

I. 2012 Hard Aluminum: What Makes It the “Representative of High-Strength Materials”?

2012 belongs to the aluminum-copper-magnesium series of hard aluminum alloys. Compared to common aluminum alloys like 6061 and 5052, its core advantages lie in “strength” and “mechanical stability,” which stem from its unique composition design and heat treatment characteristics:

In terms of composition, 2012 hard aluminum uses aluminum as the base matrix, adding 4.0%-5.0% copper (to enhance strength and hardness), 0.5%-1.0% magnesium (to improve corrosion resistance and mechanical synergy), and 0.3%-0.9% manganese (to refine grains and improve workability). It also contains trace elements like silicon and iron to fine-tune its properties. This composition allows its mechanical properties to achieve a qualitative leap after T4 or T6 heat treatment. In the T6 temper, 2012 hard aluminum can reach a tensile strength exceeding 480 MPa, a yield strength over 320 MPa, and maintain an elongation of around 10%. Its strength far surpasses that of 6061-T6 (tensile strength: 290 MPa) and even approaches some low-carbon steels, yet it weighs only about one-third as much as steel, perfectly balancing “high strength” with “lightweight.”

Regarding performance characteristics, 2012 hard aluminum boasts two other key advantages: First, excellent fatigue resistance. In scenarios involving repeated stress or vibration (such as aerospace engine mounts or mechanical drive shafts), it can maintain long-term structural stability and is less prone to crack initiation due to fatigue. Second, controllable workability. Despite its high strength, through the reasonable adjustment of extrusion and forging parameters, it can be formed into various shapes like sheets, rods, and profiles. It also allows for secondary processing such as drilling, milling, and welding. This meets the needs of complex structures without significant performance degradation from processing. However, it’s important to note that the corrosion resistance of 2012 hard aluminum is slightly inferior to that of 5xxx series aluminum alloys. Therefore, in damp or high-salt-spray environments, protective surface treatments like anodizing or painting are typically required to form a protective layer.

II. The “Primary Arena” of 2012 Hard Aluminum: Meeting High-Strength Demands Across Multiple Fields

Thanks to its excellent mechanical properties, the application of 2A12 hard aluminum has long permeated the “high-strength essential sectors” of industrial manufacturing. Its presence can be found from high altitudes to the ground, and from precision instruments to heavy equipment:

In the aerospace sector, 2012 hard aluminum is a “classic structural material.” Key components such as aircraft fuselage frames, wing skin supports, and landing gear connectors are often made from 2012-T6 sheets or profiles. On one hand, its high strength can withstand aerodynamic loads during flight and impact forces during takeoff and landing. On the other hand, its lightweight characteristics help reduce overall airframe weight, improving fuel efficiency. For example, the wing support beam of a certain small general aviation aircraft, after adopting 2012 hard aluminum profiles, achieved a 55% weight reduction compared to traditional steel, while successfully passing impact tests at 1.2 times the design load, fully meeting aviation safety standards.

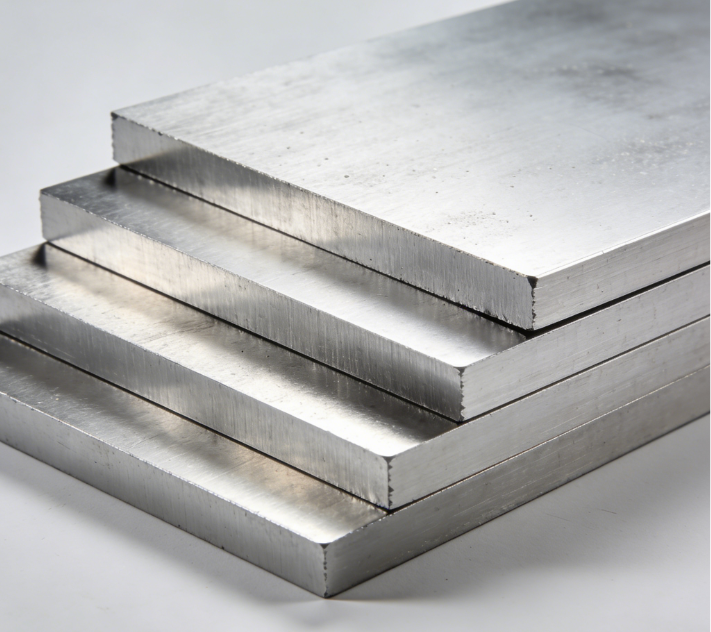

In the machinery manufacturing sector, 2012 hard aluminum is the “preferred choice for tooling fixtures and heavy-duty components.” High-precision fixtures used in factories for clamping large workpieces often utilize 2012-T6 rods for their jaws. This ensures stable clamping force (with minimal deformation) while avoiding difficulties in fixture movement caused by excessive weight. Similarly, hydraulic piston rods for heavy machinery and flange connectors for high-pressure vessels are frequently machined from 2012 hard aluminum. Its high strength can withstand high pressures (above 30 MPa), and its lightweight nature reduces inertial losses during equipment operation.

In the military and special equipment sector, the “high strength + impact resistance” properties of 2012 hard aluminum offer even greater advantages. When used in the protective armor of military vehicles, support structures for portable radar systems, or rescue equipment tools, 2012 hard aluminum provides a degree of protection against impact and collision. Furthermore, it facilitates easier transport and handling, thereby enhancing the mobility and operational effectiveness of the equipment.

III. 2012 Hard Aluminum: Process Control Ensures Stable Performance, Customization Adapts to Application Scenarios

The full performance potential of 2012 hard aluminum relies on precise production processes and quality control. Deviations in composition or improper heat treatment parameters can easily lead to issues like insufficient strength or inconsistent properties. Leveraging 40 years of experience in aluminum processing, Foshan Zhanmei Metal maintains strict control from raw materials to finished products, ensuring the stable and consistent performance of 2012 hard aluminum. It also offers customization services to meet the demands of diverse application scenarios.

Regarding production processes, Zhanmei Metal focuses on controlling two core aspects:

Precise Composition Ratio: Using high-purity aluminum ingots and high-quality copper and magnesium alloy raw materials, the company monitors composition in real-time via vacuum melting furnaces and spectrometers. This ensures strict control of copper and magnesium content within the standard range, preventing strength issues caused by impurities or compositional deviations.

Refined Heat Treatment: Optimizing the T6 heat treatment process for 2012 hard aluminum’s characteristics involves precise control of the solution temperature, adjusting holding times based on material thickness, and a 6-8 hour artificial aging stage to ensure complete internal structural transformation. This results in uniform and stable mechanical properties, with tensile strength variation kept within a fixed range for each batch.

For product forms and customization services, Zhanmei Metal offers diverse options: 2012 hard aluminum plates are available in a wide range of thicknesses and widths, suitable for aircraft skins and fixture panels; rods of various diameters can be used for components like drive shafts and bolts; custom extruded profiles can be produced based on client drawings to meet special structural needs. For scenarios requiring corrosion resistance, Zhanmei Metal provides surface treatments like anodizing or passivation to enhance the corrosion resistance of 2012 hard aluminum, making it suitable for damp workshop environments or outdoor equipment.

As industrial manufacturing advances towards “higher-end and more precise” development, 2012 hard aluminum is also continuously evolving. On one hand, through fine-tuned composition and process optimization, its corrosion resistance and low-temperature performance are being further improved, expanding its applications in extreme environments like deep-sea equipment and polar research gear. On the other hand, by combining with composite materials, it achieves further weight reduction while maintaining high strength, meeting the aerospace industry’s demand for “lighter and more efficient” solutions.

As a “strength pillar” in the industrial sector, the value of 2012 hard aluminum lies not only in its “high strength” but also in its ability to replace traditional steel with its lightweight properties, driving equipment towards “higher efficiency and energy savings.” With its deep expertise in 2012 hard aluminum production processes and customization capabilities, Foshan Zhanmei Metal is enabling this high-performance material to be implemented in more fields, providing reliable support for the “high-strength demands” of modern industrial manufacturing.