3C Electronic Aluminum Profiles: Enabling Thinner, Lighter, and Higher-Performance Innovations in Consumer Electronics

Amid the wave of “accelerated iteration and enhanced user experience” in the 3C electronics industry, products like smartphones, laptops, and smart wearable devices are continuously pushing the boundaries of form factor—from the flexible structures of foldable phones to the portable designs of ultra-thin notebooks and the miniaturized integration of smartwatches. Each innovation demands core materials that are “lighter, stronger, more precise, and better suited.” As a key carrier for structural support, heat dissipation, and protection in consumer electronics, 3C electronic aluminum profiles, leveraging their inherent advantages of light weight, high thermal conductivity, and easy machinability, along with customizable performance optimization, have gradually become a core material driving 3C product upgrades. They provide solid support for the industry’s transition from “meeting functional needs” to “delivering (ultimate experiences).”

Laptop Panel

The fundamental reason 3C aluminum profiles can serve as the “key supporting actor” in consumer electronics lies in the deep alignment between their properties and 3C product requirements. Firstly, it’s the art of balancing lightweight design with structural strength. With a density of only 2.7g/cm³, aluminum alloys reduce weight by over 60% compared to stainless steel and over 70% compared to copper. Used in smartphone mid-frames and laptop bottom covers, they can lower the overall product weight by 20%-30%, perfectly meeting the consumer demand for “thin, light, and portable.” Simultaneously, 6-series aluminum alloy profiles (e.g., 6061, 6063) treated with T5/T6 heat treatment can achieve tensile strengths of 260-300MPa and yield strengths exceeding 220MPa, resisting impacts from daily drops and squeezes, providing stable protection for delicate electronic components, and extending product lifespan.

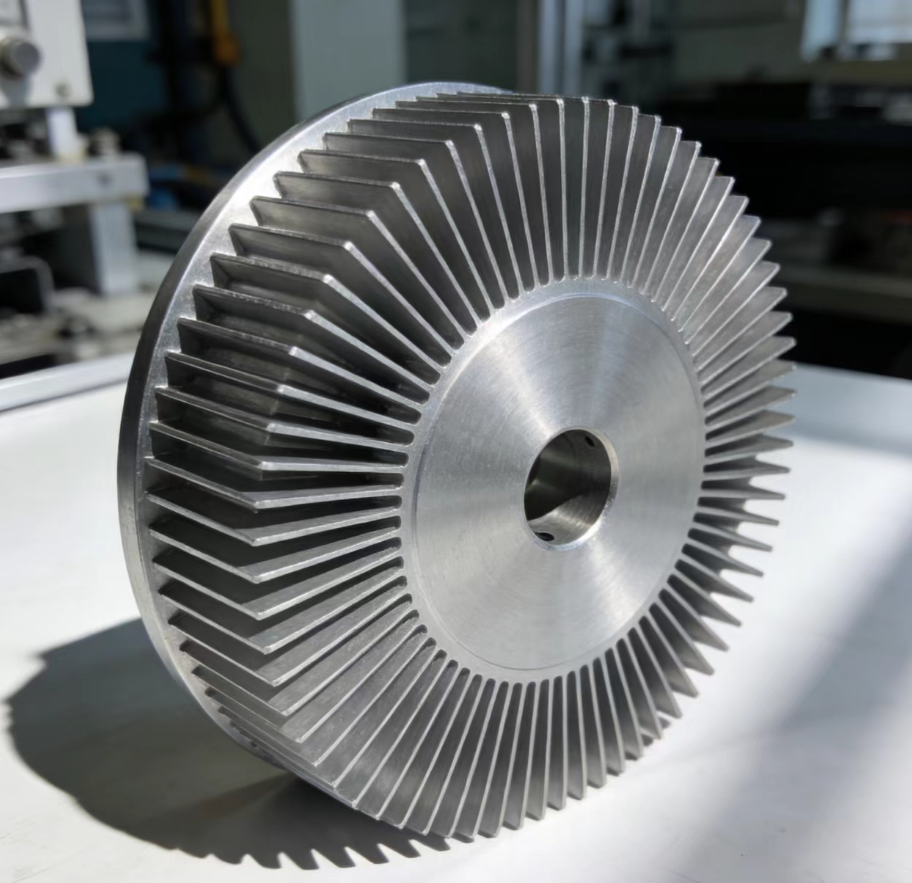

Secondly, it’s meeting the essential “heat dissipation requirement.” During operation, chips, batteries, and fast-charging modules in 3C products generate significant heat. Aluminum alloy, with a thermal conductivity of 150-200W/(m·K)—over 10 times that of plastic and 5 times that of glass—enables heat sinks and thermal backplates made from it to quickly transfer heat to the exterior, preventing devices from throttling performance or crashing due to overheating. This role is particularly indispensable in “high-power-consumption” products like 5G smartphones and high-performance gaming laptops.

Thirdly, it’s flexible processing and aesthetic plasticity. Aluminum profiles can be extruded into complex, irregular shapes—from the “integrated button slot” in a smartphone mid-frame to the “curved bezel” of smart earbud charging cases and the “ultra-thin heat dissipation fins” in laptops—all with precise forming. Surface treatment processes for aluminum are also extremely diverse: anodizing allows for 100+ color customizations (from Space Gray and Aurora Blue to gradients); sandblasting and brushing create fine textures; PVD coating can mimic precious metal luster. This meets the market competition demand where “appearance is paramount” for 3C products. Moreover, aluminum profiles offer better cost controllability than copper or titanium alloys, helping companies manage production costs while ensuring performance, aligning with the “mass production” nature of the 3C industry.

Smartphone Mid-Frame

Addressing the refined needs of the 3C electronics industry, specialized aluminum processors like JIAYOU enhance the suitability of aluminum profiles for specific applications through “deep process expertise and customized services.” In alloy formulation optimization, JIAYOU precisely adjusts compositions based on product characteristics: developing low-impurity 6061-T6 profiles for smartphone mid-frames, strictly controlling iron and copper content to ensure strength while avoiding impurities that affect surface treatment; customizing high-thermal-conductivity 6063-T5 profiles for laptop heat dissipation modules, finely adjusting the magnesium-silicon ratio to stabilize thermal conductivity above 180W/(m·K), enhancing cooling efficiency. JIAYOU also develops ultra-thin aluminum profiles (0.8mm thickness) for wearable devices, using self-produced billets from high-purity aluminum ingots (≥99.7%) to minimize internal defects like porosity and inclusions, ensuring sufficient strength and flatness even after thinning.

In precision manufacturing, Zhanmei employs imported extrusion equipment and 5-axis CNC machining centers to achieve “micrometer-level” precision in controlling cross-sectional dimensional tolerances, ensuring tight assembly between smartphone mid-frames and screens/batteries, avoiding gaps. Surface roughness is controlled to Ra≤0.4μm, providing an excellent foundation for subsequent surface treatments. Furthermore, Zhanmei has introduced automated production lines enabling continuous operation from billet heating and extrusion to surface treatment, (reducing the production cycle to 2-3 days), perfectly matching the rhythm of 3C products’ “rapid iteration and market capture.”

In customized services, Zhanmei deeply collaborates with clients on R&D needs: developing “high-ductility aluminum profiles” for foldable phone customers by adjusting heat treatment processes to increase elongation率 (rate) above 18%, accommodating the repeated bending of folding structures. It also offers one-stop solutions encompassing “material + surface treatment + cutting + inspection,” allowing clients to avoid coordinating multiple suppliers, significantly shortening R&D and production cycles. It once helped a leading smartphone manufacturer reduce the mid-frame development cycle for a new model by 15%.

SIM Card Tray

Innovations in surface treatment processes further endow 3C aluminum profiles with both “aesthetics” and “durability.” Building on conventional techniques, JIAYOU upgrades its technology: standard anodizing allows 100+ color customizations, with oxide film thickness capable of passing 48-hour neutral salt spray tests, meeting the long-term use demands of consumer electronics. Sandblasting can be adjusted per client needs by varying grit size to create diverse effects from(fine matte) to (coarse sand texture), with anti-fingerprint coating adhesion reaching Grade 5B. Brushing supports various patterns like linear, spiral, and random, with line width precision controlled within 0.05mm, enhancing a premium metallic feel.

As the 3C electronics industry evolves towards “intelligence, integration, and multi-scenario convergence,” the application boundaries of aluminum profiles continue to expand. In the foldable phone sector, JIAYOU‘s high-ductility aluminum profiles serve as “hinge support structures,” providing stable protection for flexible screens. In AR/VR devices, its lightweight aluminum profiles used in head-mounted frames reduce pressure during prolonged wear. In new energy vehicle electronics, high-temperature-resistant and vibration-resistant aluminum profiles meet th heat dissipation and structural needs of center console screens and autonomous driving chips. Even in smart home applications, JIAYOU’s aluminum profiles are used in smart speaker housings and smart door lock panels, balancing aesthetics and durability.

In today’s increasingly competitive 3C electronics landscape, the “suitability” and “innovativeness” of materials directly impact a product’s market competitiveness. 3C electronic aluminum profiles, relying on their irreplaceable performance advantages and the deep process expertise and customized services of specialized enterprises like JIAYOU, have become an “important partner” in consumer electronics innovation. Looking ahead, with the proliferation of technologies like 5G, AIoT, and the metaverse, the forms and demands of 3C products will continue to evolve. JIAYOU will remain committed to technological innovation at its core, optimizing material properties and expanding application scenarios to provide more precise and efficient aluminum profile solutions for the 3C electronics industry, driving more “thin, lightweight, high-performance, and aesthetically pleasing” products into consumers’ lives.