In industrial manufacturing and civil applications, material selection often involves striking a balance between weather resistance and workability — equipment by the sea must withstand high salt spray without rusting, outdoor frames require stable connections via welding, and chemical environments demand tolerance to weak acids and alkalis. With its dual core strengths of outstanding corrosion resistance and excellent weldability, 5052 aluminum alloy has become a versatile material across multiple fields. Whether for pipeline supports in marine engineering or support frames for outdoor photovoltaic systems, it can adapt in form and performance to address scenario-specific material challenges, offering greater possibilities for design and production.

I. Corrosion Resistance: The “Built-in Shield” of 5052 Aluminum Alloy, Suited for High-Corrosion Environments

As a representative of the Al-Mg series aluminum alloys, the corrosion resistance of 5052 is no accident—it stems from both its compositional design and microstructure, making it the preferred material for high-humidity and high-corrosion settings.

1. The Fundamentals of Corrosion Resistance: Dual Protection from Composition and Oxide Film

The magnesium content in 5052 aluminum alloy is precisely controlled between 2.2% and 2.8%. This ratio avoids the insufficient corrosion resistance caused by too little magnesium while preventing the risk of stress corrosion cracking from excessive magnesium. More importantly, it naturally forms a dense oxide film (about 5-10 nm thick) in air. This film adheres tightly to the material surface, acting as a “built-in shield” that effectively isolates moisture, oxygen, salt spray, weak acids, and other corrosive media, protecting the internal aluminum matrix from erosion.

Compared to the common 6061 aluminum alloy (Al-Mg-Si series), 5052 shows a clear advantage in corrosion resistance: in neutral salt spray tests, 5052 can withstand over 1000 hours without significant pitting or white spots, while 6061 typically shows corrosion marks after 500-800 hours. In high-salt-spray coastal environments, 5052 components can have a service life of 8-10 years—over 30% longer than 6061—significantly reducing long-term maintenance costs.

2. Precise Adaptation to Corrosive Environments: The “Weather-Resistant Performer” from Marine to Chemical Applications

Thanks to its excellent corrosion resistance, 5052 aluminum alloy is naturally suited for high-corrosion, high-humidity environments, addressing the pain points of traditional metals prone to rust:

• Marine Engineering: Deck anti-slip plates, pipeline supports inside ship cabins, and protective railings for offshore platforms are often made from 5052 sheet or tubing. Its resistance to seawater corrosion prevents structural rust from long-term immersion, ensuring navigation safety.

• Outdoor Construction: Window and door frames for coastal villas, housings for outdoor advertising lightboxes, and landscape railings in parks made from 5052 profiles require no frequent rust removal or repainting. Even after exposure to wind, rain, and sun, they maintain their appearance and structural integrity.

• Chemical & Laboratory Settings: Cooling water pipelines in chemical plants and corrosion-resistant workbench panels in laboratories. 5052 can withstand weak acid and alkali erosion, avoiding media contamination from rust while ensuring long-term safety.

II. Weldability: The “Connection Advantage” of 5052 Aluminum Alloy, Enabling Flexible Construction of Complex Structures

Unlike some high-strength aluminum alloys (e.g., 2A12 hard aluminum), which are prone to cracking and performance degradation after welding, the weldability of 5052 aluminum alloy is considered an “industry benchmark.” It is compatible with multiple welding processes, allowing for strong joint connections and supporting complex structural designs.

1. Core Advantages of Weldability: Low Crack Risk + Stable Post-Weld Performance

The weldability of 5052 is mainly reflected in two aspects: First, low hot cracking susceptibility—thermal stresses generated during welding can be released through the material’s own good ductility, minimizing weld cracks. Second, minimal post-weld performance loss—even without complex post-weld heat treatment, the tensile strength in the weld zone can reach over 80% of the base metal, far exceeding the 60%-70% typical for welded 6061 aluminum, ensuring structural strength at joints.

It is fully compatible with several common industrial welding processes, meeting diverse scenario needs:

• Argon Arc Welding (TIG/MIG): The most mainstream method, producing aesthetically pleasing, leak-tight welds. Ideal for applications requiring high joint strength and sealing, such as ship pipelines and outdoor frames.

• Resistance Spot Welding: High efficiency with a small heat-affected zone. Suitable for thin sheet joining (e.g., outdoor chassis housings, food machinery guards) without damaging the surface oxide film, preserving corrosion resistance.

• Laser Welding: High precision with narrow weld seams. Suitable for small precision components (e.g., portable outdoor power supply housings, electronic device aluminum frames), balancing joint strength and dimensional accuracy.

2. Practical Value of Weldability: “Connection Freedom” from Large Structures to Small Components

Weldability allows 5052 aluminum alloy to break free from “single-form” limitations, enabling assembly into complex structures for applications of various scales:

• Large Structural Components: Support frames for outdoor photovoltaic power stations use 5052 profiles joined via argon arc welding. They leverage corrosion resistance to withstand weathering while achieving structural stability through welding, ensuring long-term safe operation of PV modules.

• Medium-Sized Equipment: Conveyor belt frames for food processing machinery and protective housings for medical devices. Welded 5052 sheet offers easy cleaning, corrosion resistance, and allows flexible structural adjustments to fit custom designs.

• Small Components: Aluminum supports for portable camping gear and housings for household water purifiers. Achieve a balance of lightweight design and sealing through resistance spot welding or laser welding, facilitating portability and daily use.

III. Choosing the Right Form: A Guide to Matching 5052 Profiles, Sheets, and Tubes to Applications

5052 aluminum alloy can be processed into various forms such as profiles, sheets, and tubes. Different forms have distinct characteristics. Selection should consider usage scenario + structural requirements + processing methods to maximize its corrosion resistance and weldability.

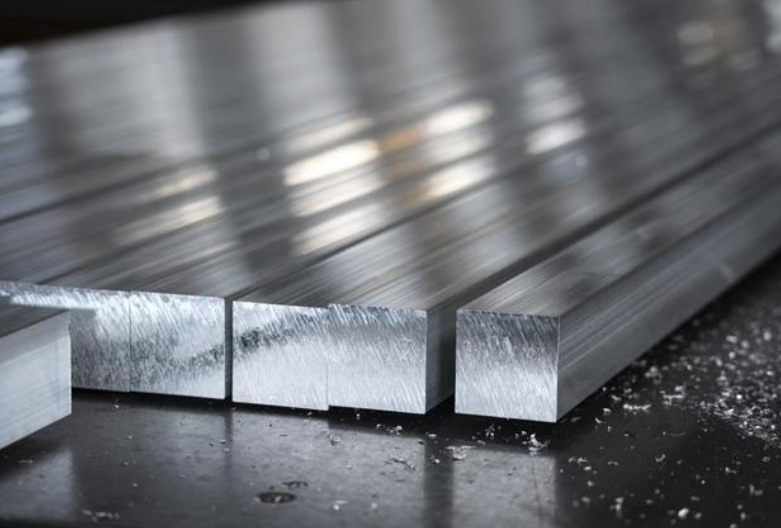

1. 5052 Profiles: The “Preferred Choice” for Frames and Support Structures

5052 profiles typically have rectangular, square, or custom cross-sections, offering both corrosion resistance and structural strength. Ideal for load-bearing applications exposed to the outdoors:

• Outdoor Frame Types: Main beams for PV mounts, support skeletons for outdoor billboards, and frames for park benches. Using 5052 profiles (e.g., 60×40 mm rectangular) allows quick assembly via welding while resisting outdoor corrosion, with a service life exceeding 8 years.

• Equipment Structure Types: Guardrails for chemical equipment work platforms and support frames for aquarium tanks in marine parks. The corrosion resistance of 5052 profiles handles damp or corrosive environments, while welding ensures strong connections with other components.

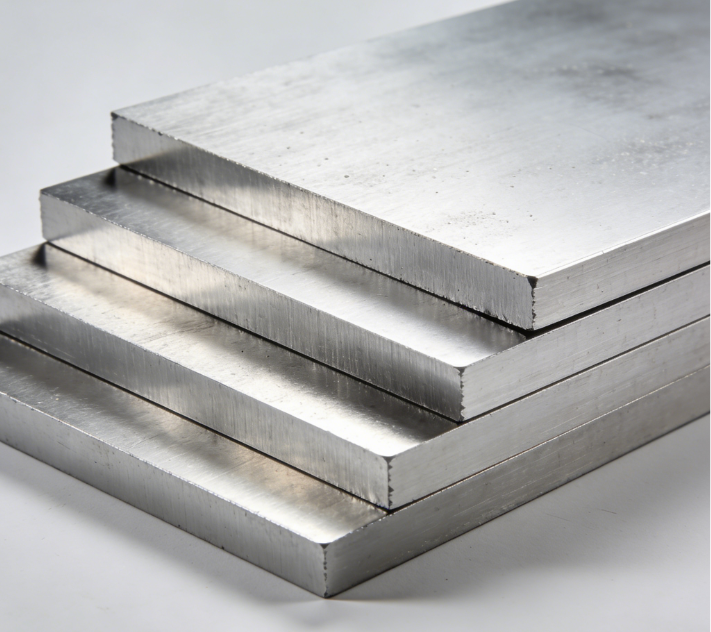

2. 5052 Sheets: The “Ideal Choice” for Flat Structures and Protective Housings

5052 sheets are available in thicknesses from 0.5 mm to 10 mm, featuring a flat surface and easy workability. Suitable for flat parts or housings requiring bending or welding:

• Protective Housing Types: Housings for outdoor distribution boxes, cabin bulkheads for ships, and guards for food machinery. Using 1-3 mm thick 5052 sheet provides good sealing after welding, and its corrosion resistance protects internal parts from rain or media erosion.

• Decorative & Work Surface Types: Corrosion-resistant workbench panels for laboratories and exterior wall cladding for coastal buildings. The surface of 5052 sheet can be brushed or anodized, combining aesthetics with weather resistance, remaining rust-free over long-term use.

3. 5052 Tubes: The “Quality Solution” for Fluid Transport and Lightweight Support

5052 tubes include round, square, and other shapes, featuring smooth inner walls and strong corrosion resistance. Suitable for fluid transport or lightweight support scenarios:

• Fluid Transport Types: Cooling water pipelines in chemical plants and freshwater delivery pipes for marine engineering. Using 5052 round tubes (10-100 mm diameter) prevents pipe clogging from corrosion, ensuring media purity.

• Lightweight Support Types: Poles for camping tents and support tubes for outdoor fitness equipment. 5052 square tubes (e.g., 20×20 mm) are lightweight yet strong. Welded into foldable structures, they are portable and durable.