As manufacturing shifts toward precision and lightweight upgrades, aluminum profiles have become a key alternative to traditional steel in fields such as mechanical manufacturing and automation equipment, thanks to their combined strength and lightweight properties. Among them, 6-series aluminum alloys (e.g., 6061), known for their moderate strength, high machining precision, and stable corrosion resistance, have become mainstream materials for custom mechanical structural components.

As the heartland of aluminum processing in South China, Foshan leverages over 40 years of accumulated manufacturing expertise, a complete industrial chain, and advanced production equipment to offer a one-stop customization service for aluminum square bars—from mold development and profile extrusion to precision machining—delivering efficient and reliable material solutions for the mechanical industry.

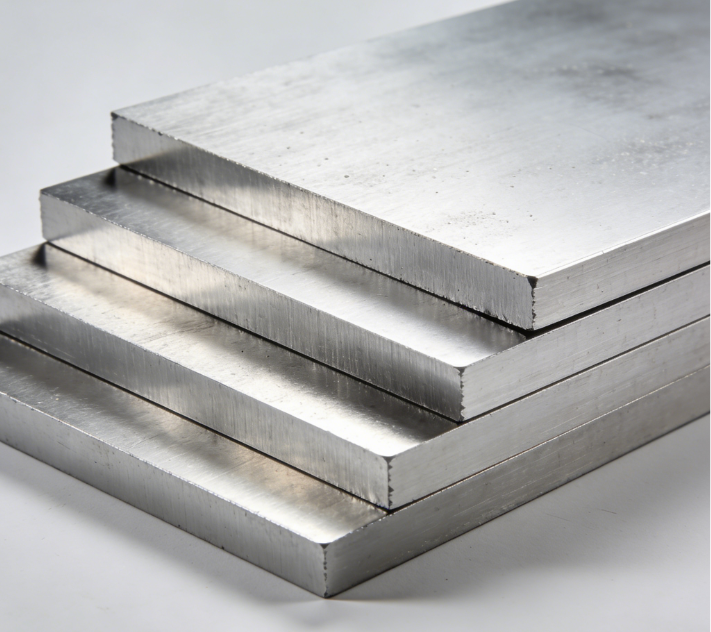

The 6061 aluminum square bar, with magnesium and silicon as its alloying elements, undergoes solution heat treatment and aging to become an ideal choice for manufacturing support structures and transmission components in the mechanical field. Its status as the preferred material stems from its outstanding comprehensive performance. In terms of mechanical properties, the 6061 aluminum square bar achieves a tensile strength of up to 260 MPa and a yield strength of approximately 240 MPa. It can withstand routine loads during mechanical operation without easily bending or fracturing, providing robust support for the stable functioning of equipment.

The 6061 aluminum square bar also offers excellent machinability. Whether milling, drilling, or tapping, it maintains good dimensional accuracy, and the surface roughness after processing can be controlled to Ra 0.2 μm, meeting assembly requirements with minimal subsequent polishing. Additionally, it possesses notable corrosion resistance. In common mechanical workshop environments—such as exposure to oil stains and light dust—a stable oxide film forms on its surface, slowing the corrosion rate. Compared to ordinary carbon steel, this reduces equipment maintenance frequency and costs. These characteristics give the 6061 aluminum square bar irreplaceable advantages in the mechanical industry.

In the production of 6061 aluminum square bars, Jiayou Industrial Aluminum has established a refined and standardized process to ensure each bar meets high-quality requirements. During the extrusion phase, customized high-precision molds are employed, with the mold cavity dimensions strictly controlled. The extrusion process utilizes an intelligent temperature control system to stabilize the extrusion cylinder temperature within the range of 370–400°C, while precisely adjusting the extrusion speed to prevent issues such as surface cracks or dimensional deviations caused by excessive or insufficient speed. After extrusion molding, the bars immediately undergo solution treatment—they are placed in a solution furnace for a specified duration, followed by rapid water quenching to enhance material strength.

During the aging treatment stage, strict control is maintained with an aging temperature of 195±5°C for 8 hours. The aging duration is adjusted based on the bar specifications to ensure the material’s mechanical properties meet design standards. In the final inspection phase, in addition to routine checks for cross-sectional dimensions and straightness, random samples are subjected to mechanical performance tests and metallographic analysis. Only when all indicators comply with the requirements of the GB/T 6892-2015 standard are the bars approved for warehousing and sale.

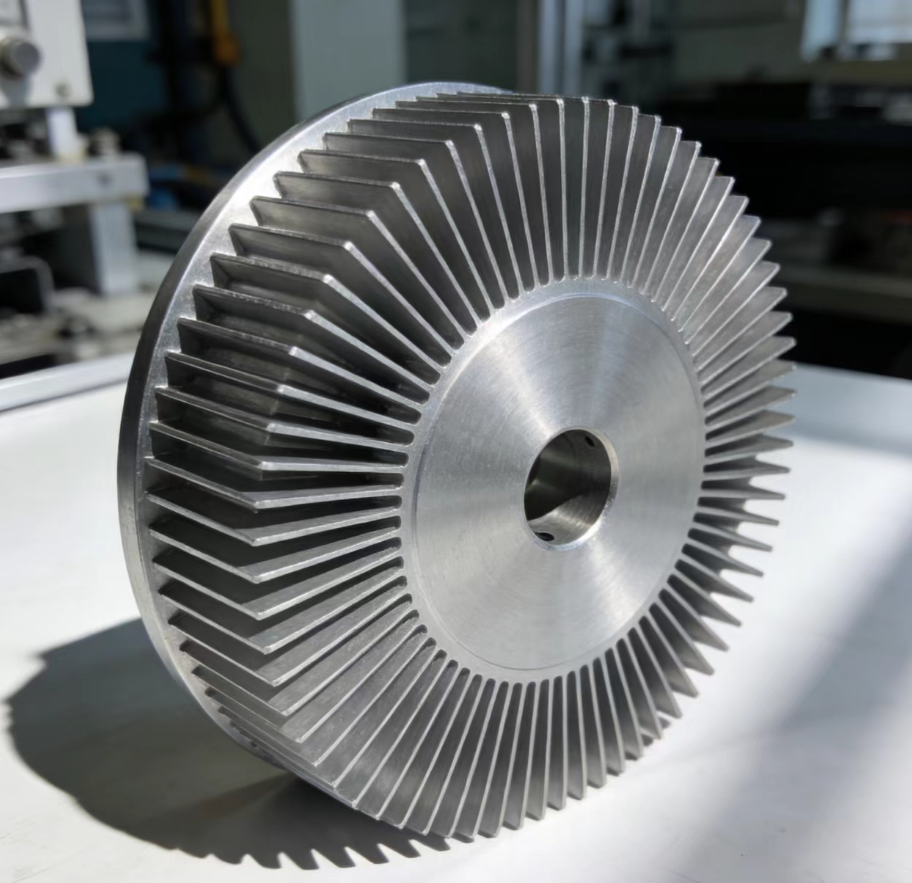

Jiayou Industrial Aluminum’s 6061 aluminum square bars are widely used in various fields, including support frames for mechanical equipment, guide rails for automated production lines, transmission rods for medical devices, and brackets for automotive components.In the field of automation equipment, Jiayou supplied 6061 aluminum square bars to an automation equipment manufacturer in Shenzhen for producing guide rail brackets on a production line. During operation, these guide rails must withstand frequent sliding friction and certain loads. Thanks to their excellent strength and wear resistance, the aluminum square bars provided by Zhanmei Metals ensured smooth rail operation. The equipment ran continuously for 12 months without any bracket deformation issues, helping the client reduce equipment failure rates.

In the automotive components sector, Jiayou once supplied 6061 aluminum square bars to a new energy vehicle parts company for manufacturing battery pack support frames. Their lightweight characteristic (with a density of only 2.7 g/cm³) helps reduce the vehicle’s overall weight and improve its range. Additionally, their good corrosion resistance ensures the frames are less prone to damage during long-term use. This batch of products passed the stringent reliability tests of the automotive industry and secured long-term orders from the client.