In today’s world of high-frequency electronic devices and high-power industrial machinery, “overheating” is a core issue threatening equipment stability—high CPU temperatures can cause computer blue screens, overheating batteries in new energy vehicles can reduce range, and excessive heat in industrial motors may lead to failures.

With its “high thermal conductivity, lightweight design, and strong adaptability,” aluminum heat sinks have become the go-to solution for cooling, spanning from consumer electronics to heavy industry. From tiny heat dissipation plates in smartphones and battery cooling plates in cars to motor heat sinks in factories, aluminum is indispensable. JIAYOU with over 40 years of expertise in aluminum processing, provides customized solutions that ensure aluminum heat sinks are precisely tailored to various scenarios, safeguarding the stable operation of equipment.

Aluminum Emerges as the Top Choice for Heat Sinks: Three Core Advantages Address Critical Needs

Heat sinks impose stringent requirements on materials—they must conduct heat rapidly, avoid adding undue burden to devices, and adapt to diverse structural and cost needs. Aluminum has outperformed competitors like copper and stainless steel to become the mainstream choice precisely because it addresses these pain points with precision:

Firstly, it strikes a balance between thermal conductivity and lightweight design. Pure aluminum has a thermal conductivity of approximately 237 W/(m·K). Even when alloyed for industrial use, it retains a conductivity of 150–200 W/(m·K), which is 5–8 times that of stainless steel, enabling rapid heat transfer from equipment. Crucially, aluminum’s density is only 2.7 g/cm³, one-third that of copper and steel. Using aluminum for heat sinks significantly reduces weight. For instance, aluminum heat sinks in laptops are about 40% lighter than copper ones, enhancing portability. In new energy vehicles, aluminum battery cooling systems can reduce weight by 5–8 kg per set, directly boosting range by 5%–8%. For drone motors, aluminum heat sinks reduce airframe load and extend flight time. For mobile or weight-sensitive devices, this combination of “efficient heat conduction + lightness” is irreplaceable. JIAYOU further amplifies this advantage by optimizing alloy compositions, ensuring that their 6000-series aluminum for heat sinks maintains stable thermal conductivity while keeping weight low.

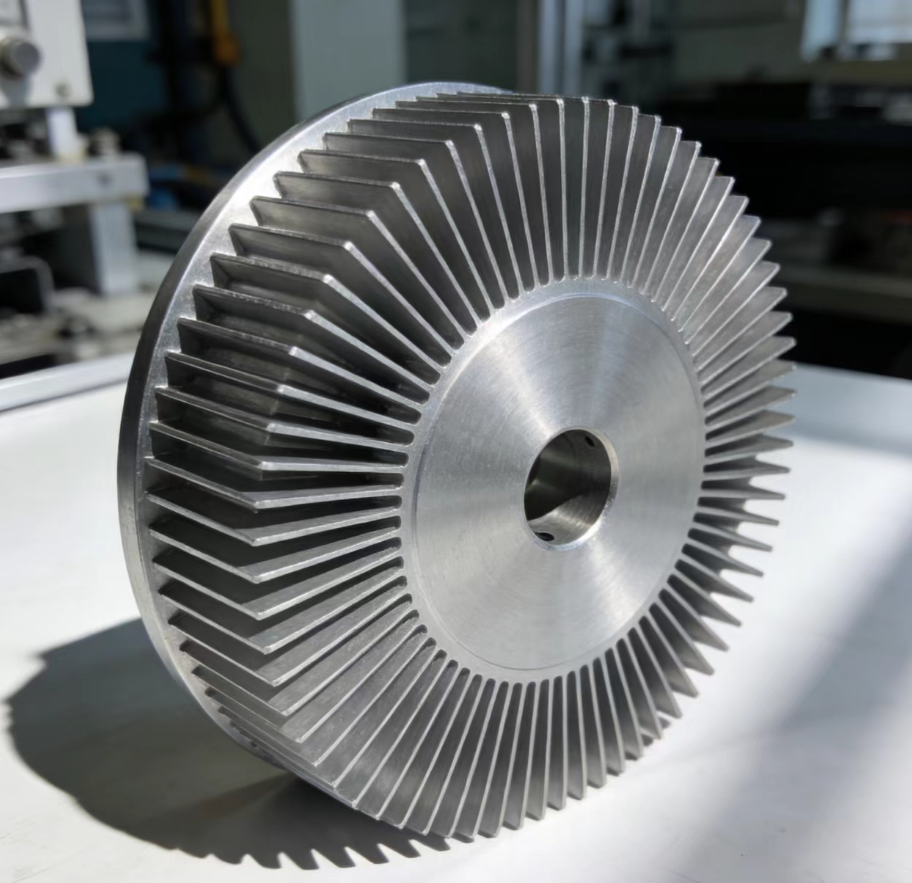

Secondly, it offers flexible processing to suit diverse structures. Heat sink structures vary widely—from dense fin arrays for computer CPUs and flat plate-tube types for batteries to custom-shaped enclosures for motors. Aluminum’s processing characteristics for profiles perfectly meet these needs. It can be formed in one go via extrusion, offering high efficiency and precision. Complex shapes can be created through bending and welding to fit device spaces. Surface treatments like anodizing and sandblasting enhance corrosion resistance and improve heat dissipation. Building on this, JIAYOU utilizes high-precision molds and slow extrusion processes to ensure uniform wall thickness and burr-free fins, perfectly adapting to the compact spaces required for customized consumer electronics like smartphones and computers.

Thirdly, it offers controllable costs suitable for all scenarios. Aluminum costs only 1/4 to 1/5 of copper and is more economical than titanium alloys. This makes it ideal for both high-volume production in consumer electronics and small-batch customization for industrial equipment. Leveraging a mature large-scale production system, JIAYOU provides tailored solutions within reasonable budgets for both large-scale industrial custom orders and small-batch heat sink aluminum material needs. They offer benefits such as waived mold fees for custom orders meeting certain quantities. This helps clients in home appliances, industrial equipment, and other sectors reduce unit costs, thereby mitigating constraints on device development caused by high material expenses.

Scenario-Based Customization: Tailoring Aluminum Heat Sinks to Device Requirements

Different devices have vastly divergent cooling needs—smartphones require “miniaturization,” automobiles demand “corrosion resistance,” and industrial motors need “high-temperature endurance.” JIAYOU delivers precise solutions for various scenarios, from alloy selection and process optimization to service responsiveness, maximizing the performance of aluminum heat sinks:

In alloy selection, JIAYOU matches materials to specific needs: For miniaturized heat sinks in consumer electronics (smartphones, computers), 6063 aluminum alloy is prioritized for its high thermal conductivity and smooth surface, suitable for compact spaces. For new energy vehicle battery cooling plates and motor heat sinks, 6061-T6 alloy is recommended. With optimized magnesium-silicon ratios, it maintains high thermal conductivity while achieving tensile strength over 290 MPa, capable of withstanding vibration and impact. Coupled with anodizing to enhance corrosion resistance, it has helped a car manufacturer’s battery cooling plates pass salt spray test requirements. For high-temperature industrial environments (e.g., metallurgical equipment), 5052 alloy is used, offering good heat resistance, stable thermal conductivity, and natural corrosion resistance suited for dusty conditions.

In process details, JIAYOU optimizes for heat dissipation efficiency: During extrusion, high-precision molds and real-time temperature monitoring ensure uniform fin wall thickness and a burr-free finish, preventing uneven heat conduction. Surface treatments are customized—consumer electronics receive black anodizing to improve radiant heat dissipation and scratch resistance, while industrial heat sinks get high-temperature-resistant coatings to prevent peeling. Quality control includes additional thermal conductivity testing, with samples from each batch tested using professional equipment. For custom products, simulation software predicts cooling performance in advance, and the team assists customers in optimizing structures to enhance heat dissipation efficiency.

In service responsiveness, JIAYOU aligns with device production cycles: In the initial phase, they thoroughly understand device heat output, installation space, and operating environment to provide structural recommendations. After product delivery, the technical department offers ongoing support and can provide on-site assistance to ensure customer satisfaction. Furthermore, leveraging its self-built South China warehousing center, JIAYOU supplies standard specifications directly from stock, with orders placed today delivered the next day, and urgent orders responded to within 24 hours. This supports the “small-batch, multi-batch” needs of precision manufacturing.

Future Trends: Aluminum Heat Sinks Advancing Toward “Higher Efficiency and Multifunctionality”

As device power density increases (e.g., 5G base stations, quantum computers), heat dissipation requirements will become more stringent—demanding not only faster cooling but also compact size, low energy consumption, and multifunctionality. This drives the evolution of aluminum heat sinks in two key directions: On one hand, optimization of material performance, such as developing aluminum-graphene composite materials with thermal conductivity exceeding that of pure aluminum by over 30%, making them suitable for high-power chips. On the other hand, integration of structure and functionality, such as creating “integrated heat dissipation aluminum components”—for instance, combining automotive battery trays with cooling plates to reduce part count and improve space utilization. There is also exploration into “smart heat dissipation aluminum,” which uses temperature-sensitive coatings to automatically adjust emissivity for dynamic thermal management.

JIAYOU will continue to leverage its 40 years of process expertise—for example, optimizing extrusion molds to create finer fins, upgrading surface treatment technologies to enhance resistance to extreme environments, and further reducing the weight of profiles while maintaining thermal efficiency. This will help advanced equipment like drones and satellites overcome heat dissipation bottlenecks. Moving forward, JIAYOU will remain committed to its core strength in customization, enabling aluminum heat sinks to be applied in more high-end scenarios. It aims to provide more reliable cooling solutions for devices in consumer electronics, new energy, industrial, and other sectors, driving the industry toward greater efficiency and stability.