As drone technology advances towards “longer endurance, greater payload capacity, and higher precision,” ranging from consumer-grade aerial photography drones to industrial surveying drones, and further to agricultural plant protection and logistics delivery drones, the material requirements for fuselage structures, power systems, and payload supports have become increasingly stringent. These materials must meet lightweight demands to extend endurance, possess sufficient strength to withstand flight vibrations and airflow impacts, and also balance cost and processing efficiency.

With its characteristics of “balanced performance, controllable cost, and flexible processing,” aluminum profiles have become one of the mainstream structural materials in the drone industry. Particularly in key components such as fuselage frames, landing gear, and motor mounts, aluminum profiles are gradually replacing some traditional materials, providing robust support for breakthroughs in drone performance.

Mainstream Basic Alloy Materials in the Drone Industry: Pros, Cons, and Selection

Currently, the commonly used basic alloy materials in the drone industry primarily fall into three categories: aluminum alloys, titanium alloys, and magnesium alloys. Due to their differing properties, each material is better suited for specific application scenarios.

Titanium Alloy: Represented by TC4 (Ti-6Al-4V), it offers a tensile strength of up to 860 MPa and excellent corrosion resistance, making it suitable for heavy-lift drones operating in extreme environments (e.g., high-altitude low temperatures, marine salt spray). However, its density (4.5 g/cm³) is higher than that of aluminum alloys, which increases the drone’s airframe weight and consequently shortens flight endurance. Furthermore, titanium is difficult to machine and extremely costly (raw material prices are over 10 times that of 6-series aluminum alloys). Its use is therefore limited to a small number of military-grade and high-end industrial drones, making it difficult to popularize in the consumer-grade and small-to-medium industrial markets.

Magnesium Alloy: Represented by AZ31B, with a density of only 1.8 g/cm³, it is the lightest of the three materials and theoretically best meets the lightweight requirements for drones. However, magnesium alloys have lower strength and poor fatigue resistance, making them prone to crack development due to vibration during flight. They also exhibit weak corrosion resistance, being susceptible to oxidation and rust in humid or outdoor environments, necessitating additional complex surface treatments (such as micro-arc oxidation), which increases processing costs. Additionally, magnesium alloys are challenging to process, prone to defects like shrinkage cavities and deformation, resulting in relatively low production yields. Currently, they are only used sparingly in micro consumer-grade drones where weight is an extreme concern and struggle to meet the high-strength demands of industrial drones.

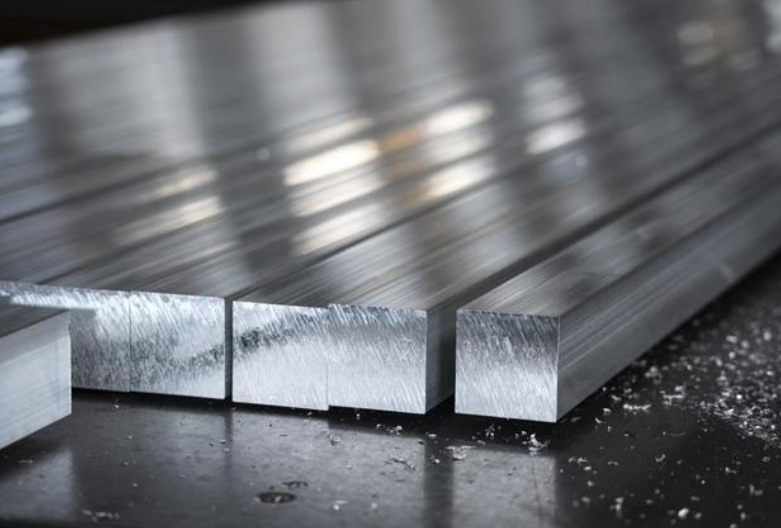

Aluminum Alloy: Represented by the 6-series (e.g., 6061, 6063) and 7-series (e.g., 7075), aluminum alloys are currently the most widely used alloy material in drones. 6-series aluminum alloys (e.g., 6061-T6) offer tensile strengths up to 290 MPa and an elongation of 12%-15%, providing a good balance of strength and machinability, making them suitable for load-bearing components like fuselage frames and landing gear. 6063-T5 aluminum alloy, known for its high surface finish and good formability, is often used for drone shells and decorative structures. The core advantage of aluminum alloys lies in their “balanced performance”—their strength meets the demands of most scenarios, their density (2.7 g/cm³) is only half that of titanium alloys and one-third that of steel, their cost is merely 1/5 to 1/8 that of titanium alloys, and their processing difficulty is far lower than that of magnesium alloys. This makes them the “cost-effective choice” for small-to-medium payload drones.

Core Advantages of Aluminum Profiles in Drone Applications: Precisely Meeting Flight Requirements

The reason aluminum profiles have become a core material for key drone components lies in the inherent alignment of their form and properties with the flight characteristics of drones:

Balanced Lightweight Design and High Strength, Extending Range: Aluminum profiles can be extruded into hollow structures (e.g., rectangular tubes, shaped tubes), further reducing weight while ensuring strength. For instance, a drone fuselage frame made from 6061-T6 aluminum alloy is over 60% lighter than a steel frame of equivalent strength and 40% lighter than a titanium alloy frame, directly enhancing the drone’s flight endurance. Taking consumer-grade aerial photography drones as an example, a fuselage frame made from 6063-T5 aluminum profiles, weighing only 150-200g, can withstand impacts 5-8 times its own weight, meeting the demands of routine flight and minor collisions.

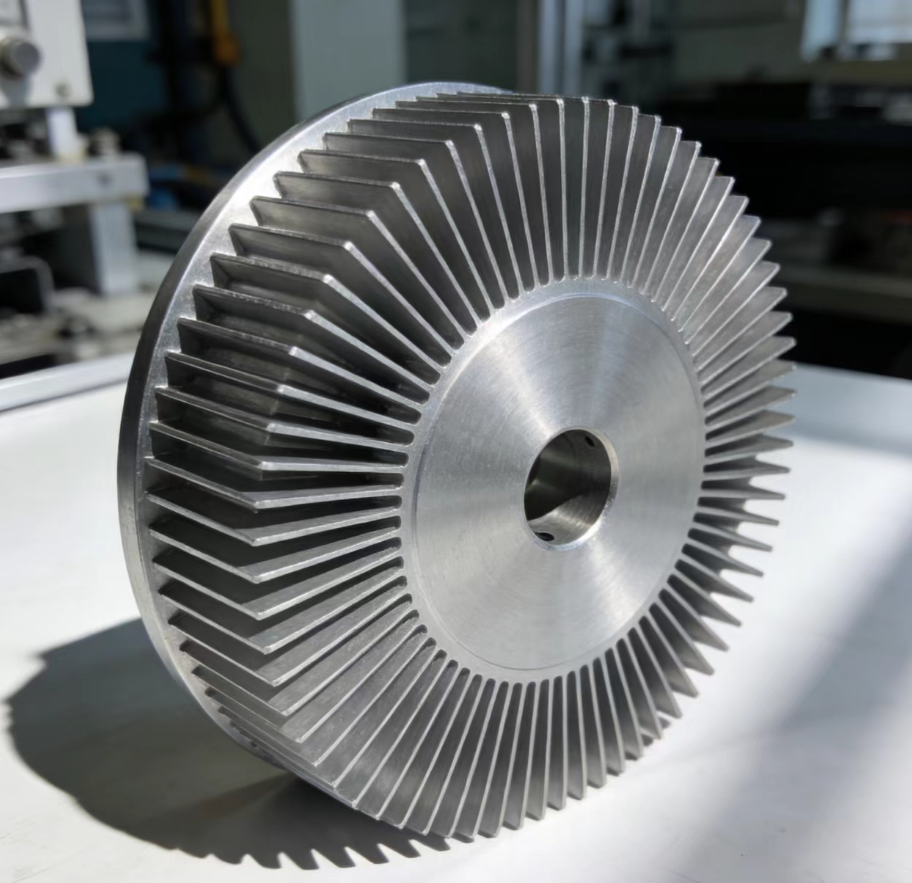

Forming Complex, Shaped Structures for Compact Design: The internal space of a drone fuselage is confined, requiring the integration of numerous components such as motors, batteries, flight controllers, and sensors. This places extremely high demands on structural “compactness” and “compatibility.” Aluminum profiles, through custom mold design and extrusion, can create complex cross-sections (e.g., motor mounts with clip slots, battery bay frames with cooling fins), integrating multiple functions into a single profile. This reduces the number of parts needing assembly, minimizing assembly errors and weight.

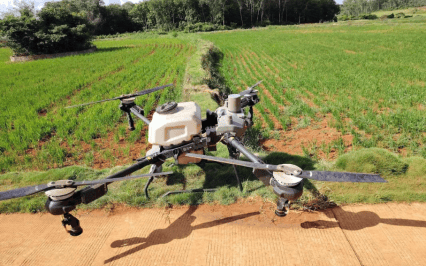

Excellent Vibration Resistance and Weather Durability, Ensuring Flight Stability: Drones face continuous vibration during flight (from motor operation, airflow disturbance) and outdoor environmental challenges (temperature changes, rain, dust). 6-series aluminum profiles, after T6 heat treatment, show significantly improved fatigue resistance. Surface treatment via anodizing creates an oxide film 10-15μm thick, with salt spray resistance exceeding 48 hours. In scenarios like agricultural plant protection (high humidity) and marine surveying (high salt spray), this effectively protects against environmental corrosion, extending component service life.

Flexible Processing and Controllable Costs, Suiting Batch Production: Aluminum profiles can be assembled using simple processes like cutting, drilling, and bending, eliminating the need for complex techniques. Their processing cycle is only one-third that of titanium alloys. Furthermore, the raw material cost for 6-series aluminum alloys is low, and mold development costs are significantly lower than for magnesium or titanium alloys. This makes them well-suited for the “multi-model, small-to-medium batch” production model common in the drone industry. For example, consumer drone manufacturers using standardized 6063 aluminum profiles can achieve daily production of thousands of frames, substantially reducing unit costs.

Enhancing Drone Performance with Customized Aluminum Profiles

Leveraging its “full-chain service capabilities” and “expertise in customization,” Jiayou Industrial Aluminum has developed a series of highly adaptable aluminum profile products tailored to the drone industry’s needs, becoming a reliable partner for numerous drone manufacturers.

Regarding alloy selection and performance optimization, Jiayou provides precise alloy solutions based on the requirements of different drone components. For instance:

For fuselage frames and landing gear, Jiayou utilizes 6061-T6 aluminum alloy to produce high-strength profiles. By strictly controlling iron content and optimizing heat treatment processes, they ensure stable tensile strength and improved elongation. This meets load-bearing demands while providing sufficient toughness to prevent fracture during flight collisions.

For drone shells and motor mounts, 6063-T5 aluminum alloy is employed. Through precision extrusion processes, the profiles achieve a low surface roughness (e.g., Ra ≤ 0.4μm), reducing subsequent surface treatment steps while ensuring shell flatness and aesthetic appeal.

For the wing spars of heavy-payload industrial drones, Jiayou can provide customized 7075-T6 aluminum alloy profiles. Combined with homogenization annealing processes, this enhances the material’s fatigue resistance, making it suitable for high-altitude, long-endurance flight requirements.

In terms of customized mold development and processing services, Jiayou relies on its mature mold R&D system to quickly respond to drone manufacturers’ needs for specialized cross-sectional shapes. A dedicated technical team provides tailored services, designing solutions based on the customer’s specific application scenarios.

Customers need not worry about quality or industry suitability upon receiving the products. Every batch of customized aluminum profile samples for drones from Jiayou undergoes rigorous testing: mechanical property tests (tensile strength, elongation), dimensional accuracy checks, straightness error measurements, and weather resistance tests, ensuring the profiles meet drone flight requirements.

Currently, Jiayou’s aluminum profiles are widely used in components such as consumer-grade aerial drone fuselage frames, agricultural plant protection drone landing gear, and industrial surveying drone wing supports, helping clients achieve breakthroughs in lightweight design, stability, and cost control.

As the drone industry advances towards “greater payload capacity, longer endurance, and operation in more complex environments,” material performance requirements will further increase. Jiayou Industrial Aluminum will continue to optimize its aluminum profile processes, develop new materials better suited for various drone applications, and deepen cooperation with drone manufacturers. Through a model of “demand anticipation, joint R&D, and rapid delivery,” Jiayou aims to provide more precise aluminum profile solutions for the drone industry, propelling drone technology to higher levels of development.